Simulation, optimization and forecasting play an essential role in both the planning and adaptation of processes in production and industry. The optimal utilization of production capacity as well as the efficient use of resources is important for companies to be able to compete in the market.

Simulation as the basis for optimization and forecasting

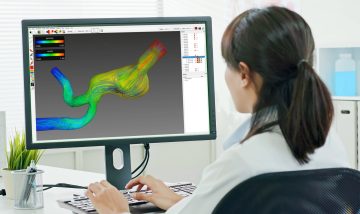

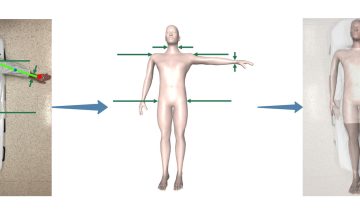

Accurate simulations of manufacturing processes are important prerequisites for manufacturing quality, process reliability and production efficiency in many areas of industry. Simulation refers to the replication of a real system or process, for example by a digital twin, to make predictions about its behavior and performance. Optimization is the effort to improve the performance of a system or process by adjusting variables to achieve specific goals such as minimum cost, resources, or energy use. Forecasting refers to the prediction of future events or trends based on historical data and models.

Customized production planning software

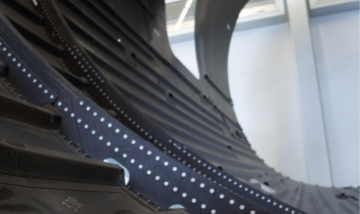

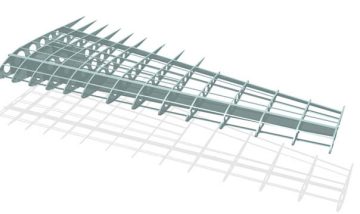

RISC Software GmbH implements customized production planning software for its customers on the basis of mathematical optimization algorithms. In addition to use cases in production planning, it also develops individual software for simulation and optimization in virtual product development. Special use cases are, for example, structure and shape optimization to determine the best design for the given use cases.

Increase of process and product quality

The use of innovative technologies is a prerequisite for increasing process and product quality and therefore an important step towards implementing comprehensive software solutions. Overall, simulations and optimizations in production offer numerous advantages for decision-making, the design and optimization of systems and processes. By using them, companies can reduce costs, increase efficiency, improve quality, shorten delivery times, increase flexibility, minimize risks and improve the safety of systems and processes.