Project opt1mus

The opt1mus project is developing a holistic system for the light metals industry. Its goal is to use digital twins and artificial intelligence (AI) to make production more efficient and reduce emissions.

Aluminum and other light metals play a vital role in achieving the 2050 climate targets. They are used in lightweight yet robust vehicle components. At the same time, their production and processing are highly energy-intensive. Efficiency can improve significantly through cyber-physical systems (CPS). Until now, manufacturers relied on years of experience and costly experiments to find the right process parameters for producing high-quality components.

Virtual Testing with Digital Twins

Today, these trials can take place virtually using digital twins of production equipment. This approach saves time and energy while avoiding hazardous working conditions when testing new alloys or processes. Digital twins also provide another benefit. When combined with live measurements during operation, they capture correlations faster and more precisely. With the help of AI, the system predicts how a process will evolve and recommends parameter adjustments. Humans need years of practice to reach a similar level of knowledge.

Need for Holistic Systems

Although methods for digitization exist, the light metals industry still lacks holistic systems. One reason is that software providers often tailor their tools to established, high-revenue sectors such as steel. Yet, the need for digital assistance systems is just as strong in other areas. Therefore, a flexible solution is required – one that adapts to innovative processes and new alloys. At the same time, it must meet the needs of operators to deliver real improvements. This is precisely the aim of the opt1mus project.

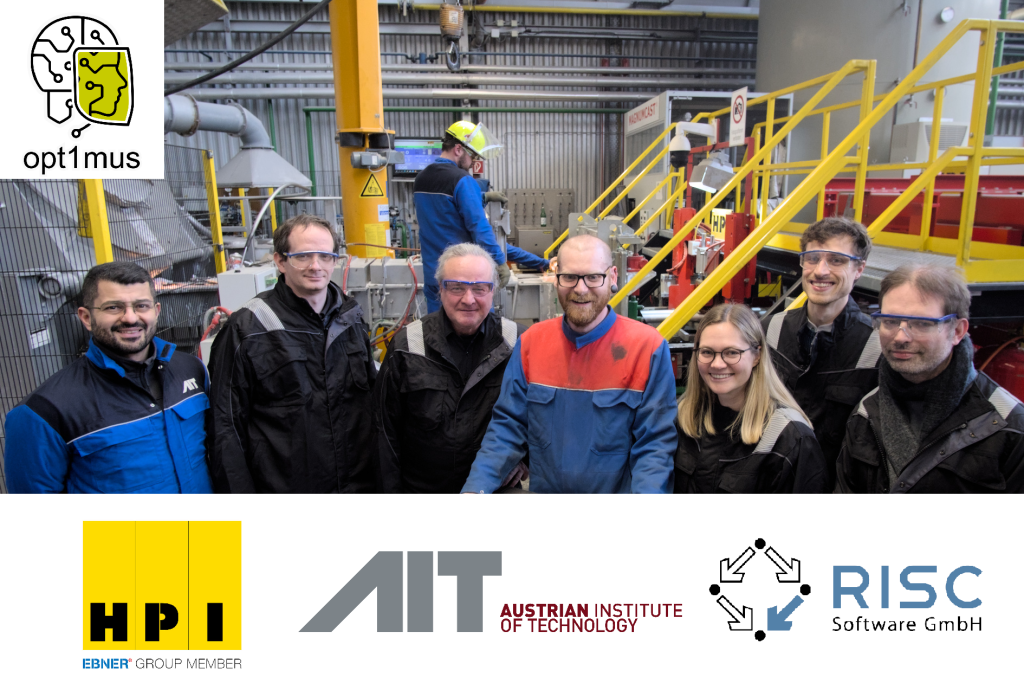

Consortium Expertise

The consortium brings together all the necessary expertise to create a human-friendly CPS, demonstrated through horizontal continuous aluminum casting:

- RISC Software GmbH, as an institute specializing in big data, AI, and machine learning, is developing an advisor system. It provides well-founded assistance for the complex decision-making required in daily casting operations.

- LKR contributes more than 25 years of experience across the full process chain. Its expertise ranges from alloy development to casting and forming processes, including simulations. This knowledge ensures accurate models for predicting material quality. HPI High Performance Industrietechnik GmbH adds 20 years of experience in building continuous casting plants.

- AIT’s Center for Technology Experience develops intuitive human-machine interfaces (HMI). Using a user-centered design process, operators receive practical support during casting.

Benefits for Industry and Sustainability

For the industrial location of (Upper) Austria, developing a flexible CPS is crucial to support digitalization across supplier companies. The CPS created in the opt1mus project will be released as open-source software. Furthermore, it will be adaptable to processes beyond continuous casting. This innovation ensures reduced scrap and lower CO₂ emissions. At the same time, it increases resilience to resource scarcity while guaranteeing reproducible, high-quality results. Ultimately, opt1mus strengthens innovation among Austrian plant engineers and producers and creates people-friendly workplaces through digital assistance.

This work was funded by the FFG (Austrian Research Promotion Agency) under the grant 899054 (opt1mus).

Project Details

- Project short titlel: opt1mus

- Project long title: Open Process Twin Minding the User 1st

- Funding call: FFG, Produktion und Material 2022

- Projekt partners:

- LKR Leichtmetallkompetenzzentrum Ranshofen (Konsortialführung)

- HPI High Performance Industrietechnik GmbH

- AIT/Center for Technology Experience

- RISC Software GmbH (Unit Data Intelligence)

- Budget volume (total): 1,2 Mio. Euro

- thereof funding volume (total): 916.000 Euro

- Duration: 36 Monate (01.03.2023 – 28.02.2026)

Contact

Project management

DI Paul Heinzlreiter

Senior Data Engineer