EU project metaFacturing: Digitalization in metal part production

Das von der EU geförderte Horizon Europe Projekt „Data and Metadata for advanced Digitalization of Manufacturing Industrial Lines“ (metaFacturing) hat als Ziel, die Digitalisierung im Bereich der Metallteilerzeugung – Gießen und Schweißen – voranzutreiben.

Im Besonderen sollen dadurch Ausschuss und Kosten reduziert sowie die Bedienung vereinfacht werden. Dies soll durch die Entwicklung eines digitalen Zwillings erreicht werden, welcher auf effizienter Prozesssimulation sowie Datenstandardisierung und Datenzusammenführung aufsetzt.

Dieser Ansatz soll alle verfügbaren Prozessdaten, wie Materialdaten, Prozessmessungen, Qualitätskontrolle und Produktvalidierung zusammenführen, um ein automatisches Feedback für die Prozesskontrolle zu ermöglichen. Zusätzlich soll das Prozessmodell auch für die Schulung von Mitarbeitern in der Fertigung eingesetzt werden.

Als Demonstratorprojekte sind geplant:

- Gießen von Metallteilen:

Entscheidungsunterstützung zur Prozessverbesserung im Gießen von Metallteilen, mit dem Ziel, die Produktqualität zu verbessern. - Schweißen von Strukturteilen:

Verbesserung der Effizienz des Produktionsprozesses sowie Produktqualitätsverbesserung durch Zusammenführen von Daten aus der Prozessplanung, dem laufenden Prozess und der Qualitätsanalyse. Die Rückführung der Ergebnisse in den Prozess erfolgt durch die Rekonfiguration von Sensoren und Aktuatoren.

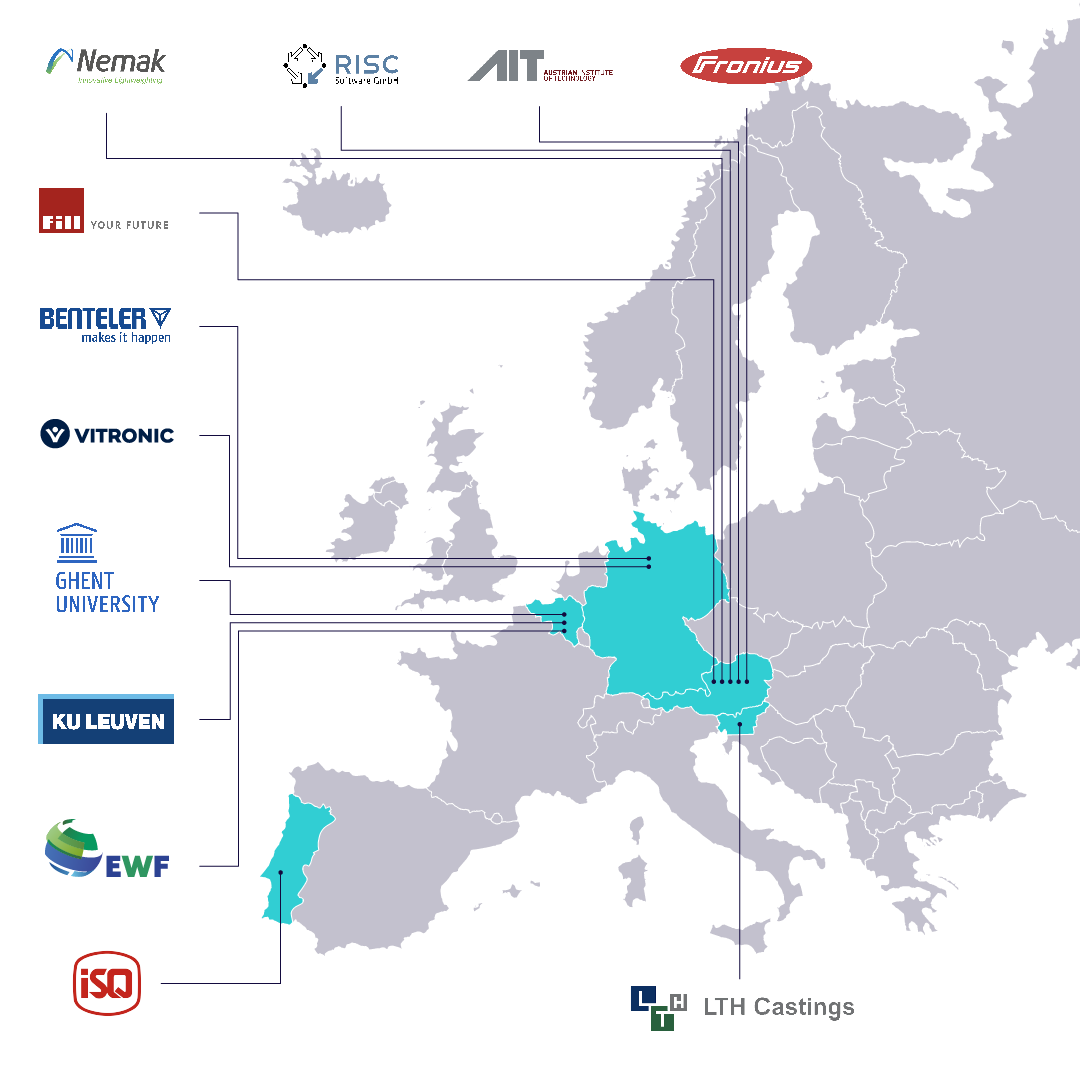

Das Projektkonsortium umfasst 13 internationale Partner aus fünf Ländern, wobei Industrie- und Anwendungspartner mit Forschungsinstitutionen zusammenarbeiten. Durch die Beteiligung von lokalen Industriepartnern wie Fill GmbH, Fronius GmbH und Nemak hat auch der Wirtschaftsstandort Oberösterreich die Möglichkeit von dem Forschungsprojekt metaFacturing zu profitieren.

Die RISC Software GmbH wird in dem Projekt ihre Kompetenzen in den Bereichen mathematischer hybrider Modellierung von Fertigungsprozessen sowie der Datenanalyse und Data Engineering einbringen, dies beinhaltet auch Datenvorverarbeitung und -integration.

Die RISC Software GmbH übernimmt im Rahmen des Projekts verschiedene Aufgaben und fungiert als Leiter des Arbeitspakets WP3, das sich mit der Definition der Datenverarbeitungsstrategie befasst. Außerdem kümmert sich die RISC Software GmbH um die Datenbereinigung und -integration, um eine nahtlose Zusammenarbeit der verschiedenen Systeme zu gewährleisten. Ein weiterer wichtiger Aspekt der Arbeit von RISC Software ist die Untersuchung und Erweiterung von KI-Algorithmen und Technologien, um die automatische Umwandlung von Informationen über den Prozess zu verbessern und somit die Einstellungen zu optimieren.

Co-finanziert von der Europäischen Union.

Das Forschungsprojekt wird von der Europäischen Union mit der Nr. 101091635 gefördert.

Projektpartner

Details zum Projekt

- Projekt-Kurztitel: metaFacturing

- Projekt-Langtitel: Data and Metadata for advanced Digitalization of Manufacturing Industrial Lines

- Fördercall: HORIZON-CL4-2022-RESILIENCE-01

- Projektpartner*innen:

- KU Leuven (Konsortialführer)

- LKR Leichtmetallkompetenzzentrum Ranshofen GmbH

- AIT Austrian Insitute of Technology GmbH (Drittleister)

- Universität Gent

- EWF (European Federation for welding joining and cutting)

- Fronius International GmbH

- Nemak Europe GmbH

- Benteler Automobiltechnik GmbH

- VITRONIC Dr.-Ing. Stein Bildverarbeitungssysteme GMBH

- FILL Gesellschaft m. b. H.

- Instituto de Soldadura e Qualidade

- LTH Castings, ULITKI D.O.O.

- Budgetvolumen (gesamt): 5.768.142,75 Euro

- davon Förderung (gesamt): 4.997.762 Euro

- Laufzeit: 36 Monate (01/2023 – 12/2025)

Kontakt

Projektleitung

Dr. Roxana Holom, MSc

Data Sciene Project Manager & Researcher