Sprecher Automation cutting pattern optimization

For Sprecher Automation GmbH, an automatic side goods optimization was developed. It ensures the ideal cutting pattern yield for an automatic saw line.

Sawmills also face the challenge of making ideal use of all their resources. In order to achieve maximum added value, existing roundwood must be processed as quickly as possible, with the lowest possible waste and into the most profitable products. In addition to production adapted to the market, local dynamic changes such as stock levels and machine conditions must also be taken into account at short notice.

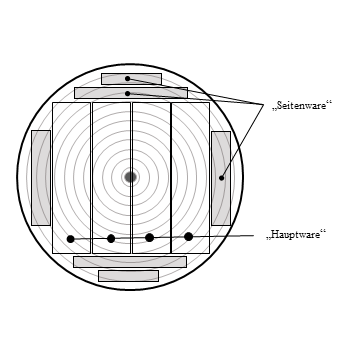

The processing sequence along a chipping line can be summarized into the following exemplary steps: Log infeed, debarking, turning, chip removal, side cut, main cut, and removal by conveyor to the lumber sorting line. The valuable main product is obtained from the inside of the log. Lateral goods are sawn timber at the edge of the roundwood with a defined forest edge portion:

Here, the forest edge means the part of the sawn timber with the original surface of the log. The main product is usually cut sharp-edged without forest edge, since it fits into the interior of the diameter-sorted log. However, because each log has its own curvature, the ideal position and size of the sideboard vary. Especially when sharp-edged sideboard with best price is required, optimization becomes essential.

During conveying on the chipper line, often at 2.5 meters per second or faster, optimization is time-critical. The system must determine not only the most profitable sideboard but also its ideal position. At the same time, cutters must be positioned correctly within the cycle time.

Innovative collaboration for a high-performance optimization solution

In cooperation with Sprecher Automation, RISC Software GmbH developed a high-performance optimization solution for price-optimal cutting of side goods. The system considers the large product variety of possible side boards, given by dimensions, price valences, and forest edge limits. At the same time, the solution ensures shortest computing times, clearly below one second per log.

Several coordinated and interlocked software components work together seamlessly. A robust multi-core architecture combined with efficient memory management provides the foundation for rapid calculations. Based on this, the intelligent search algorithm delivers optimal product and cutter positions, and it also confirms global optima. In most cases, this occurs within milliseconds.

Since spring 2019 and 2021, the optimization software has been successfully deployed at two plants. It reliably supports optimal log yield in daily operation, while further installations are already planned for the future.

Contact person

Dr. Roman Stainko

Mathematical Optimization Specialist