NC machining simulation

Simulation and collision avoidance for computer-controlled, multifunctional complete machining centers

Years of constructive cooperation, characterized by excellence, perseverance, and trust, have produced two internationally competitive software products: CrashGuard Studio and CrashGuard Online Collision Avoidance. The combination of detailed offline simulation in the CAD/CAM area and high-performance real-time simulation for collision avoidance supports customers of WFL Millturn Technologies GmbH & Co. KG. In close cooperation with experts from RISC Software GmbH, these innovations improve resource conservation and error prevention. Consequently, they increase productivity and competitiveness while strengthening market leadership.

CrashGuard Studio

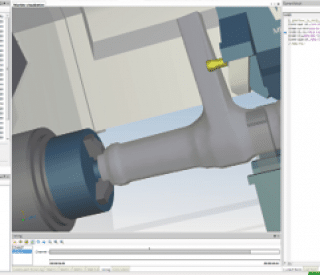

CrashGuard Studio is a 3D simulation software for multifunctional CNC turning, drilling and milling centers, which enables machines with their complex kinematics and exCrashGuard Studio is a 3D simulation software for multifunctional CNC turning, drilling, and milling centers. It enables very realistic simulations of machines with complex kinematics and numerous machining options.

A key milestone in its development was the integration of material removal simulation, implemented using the Virtual Modeling Library. Thus, users can observe ongoing material removal in real time, similar to a real machine. At the end of a process, the software provides a 3D model of the finished part, which serves as an additional option for NC program verification.

CrashGuard Studio supports:

- Verification and optimization of NC programs, increasing quality and efficiency while reducing rejects and collisions.

- Development and design of new machines, as engineers can test motion and machining capabilities before production.

- Training of operators and programmers, who can safely explore machine possibilities without risks.

Product development and maintenance take place largely in cooperation with RISC Software GmbH. Experts solved numerous challenges in geometry, algorithms, and software architecture. Moreover, continuous improvements and planned extensions underline the successful and trusting partnership.

CrashGuard online collision avoidance

The CrashGuard machine extension for online collision avoidance, another product developed in cooperation between WFL Millturn Technologies GmbH & Co. KG and RISC Software GmbH. This is a real-time collision avoidance system integrated into the machine control system, the aim of which is to avoid collisions between machine parts of complete machining centers at all times and under all circumstances. To ensure that the simulation model used can always be a little bit ahead of reality, it was necessary to develop new computational methods that are adapted to the special hardware resources of NC machine controllers.

The highly optimized core application, including algorithms and data structures, as well as the corresponding preprocessing, were developed in close cooperation with mathematicians and computer scientists at RISC Software GmbH in order to meet the enormous demands on the correctness and reliability of the system. The patented system has been successfully on the market since 2005 and is offered as an option for the complete machining centers. Currently, hardly any new machine is delivered without this option, which has increased the number of machines with CrashGuard support to over 200.

Project partner

Project details

- Project short title: Simulation von NC-Bearbeitungen

- Project long title: Simulation und Kollisionsvermeidung für rechnergesteuerte, multifunktionale Komplettbearbeitungszentren

- Project partner:

- WFL Millturn Technologies GmbH & Co KG

- Duration: ongoing

Contact person

Joachim Mairböck, MSc

Software Engineer