Application Engineering Tool

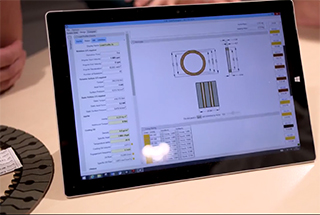

Miba application engineers can now use the application engineering tool to define, analyze, and evaluate the requirements and design of tribological systems such as brakes and clutches directly together with customers.

Digitization is changing the world we know

Digitization is penetrating more and more areas of life and business. For the industry, it offers the chance to tailor products more precisely to customer needs and to produce them more efficiently. Digitization is therefore not only a challenge but also a major opportunity.

For Miba, a strategic partner of the international engine and vehicle industry and a technology leader in friction systems, digitization is a key issue. Together with RISC Software, the team realized a tool for the system-aided development of friction systems. This solution significantly improves efficiency, standardization, and transparency in the design process.

Moreover, the know-how stored in the software is now accessible to all employees worldwide. Consequently, engineers can focus on demanding, value-adding activities and bring new products to market faster.

Long-term cooperation as a success factor

RISC Software has been supporting Miba since early 2014 in the agile implementation of the project. In a preliminary project, both partners refined the concept that Miba had prepared in advance and realized the first prototype. The actual implementation started at the beginning of 2015. Thanks to close and intensive cooperation, the first expansion stage of the software was successfully rolled out within the Miba Group in early 2016. Since then, all branches of Miba’s friction lining group worldwide have been using the system successfully.

The application engineering tool is based on a powerful and flexible calculation core. It determines characteristic system parameters and prepares them as meaningful visualizations such as diagrams and plots. At the same time, the system goes one step further: it proposes specific covering technologies and coverings while taking into account the parameters entered by the user.

The support of the user has meanwhile gone so far that concrete covering technologies and coverings are proposed, taking into account the parameters entered.

Cost module as the next step

In recent years, development has focused on a cost module. In addition to technical aspects, the software now also supports cost-related evaluations of planned designs and highlights potential savings and optimization opportunities. Thus, customer requirements and production costs can be aligned more effectively.

The prerequisite for this functionality is a detailed modeling of production facilities and processes. This makes it possible to determine and evaluate alternative production variants for the planned design. Before the cost module itself was implemented, the team realized a tool for modeling production.

At the heart of this tool lies a domain-specific language (DSL). With it, domain experts at Miba can describe production processes, production rules, and the behavior or limitations of production equipment in a highly precise and realistic manner.

Project partners

Project details

- Project short title:

- Project long title:

- Project partner

- Miba AG

- Duration:

Contact person

DI (FH) Josef Jank

Senior Software Architect & Project Manager